Have you ever wondered what's the cost of your own work? Labor costs around the world vary and the differences are quite extensive.

In economic lingo, it's called total labor cost — the total expenditure borne by employers for employing staff.

Besides the salary, it includes bonuses and other non-wage costs of employment. This means social contributions, benefits, payroll and other related taxes.

Let's now have a look at the differences between labor costs in various countries and see what companies do to keep them under control.

Different country, different labor costs

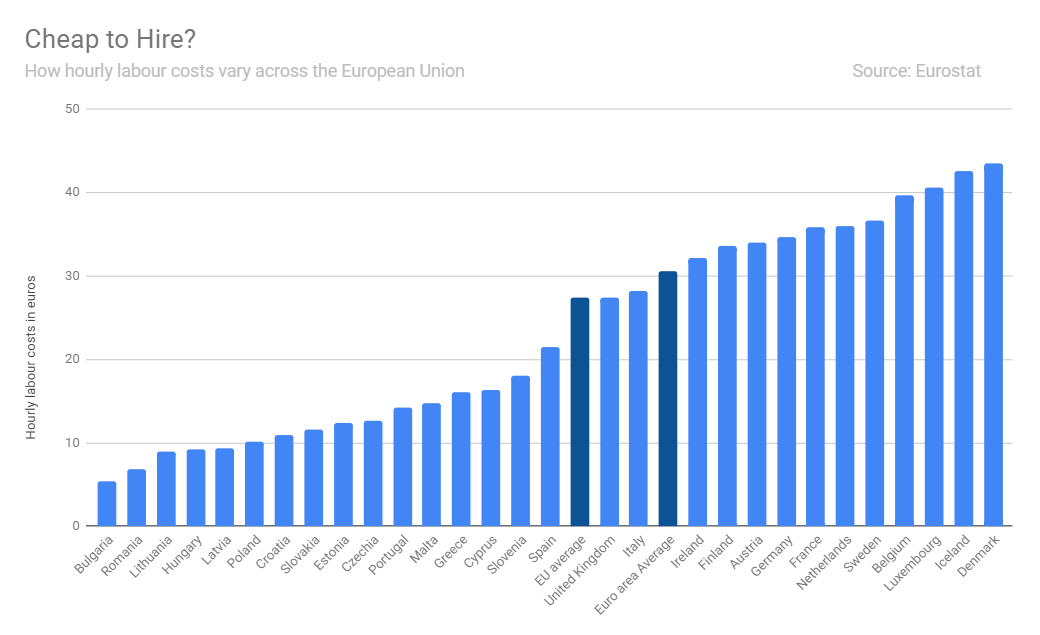

Eurostat has gathered data from the whole of the EU and the results might surprise you. There are vast differences between the most costly and cheapest labor across the old continent.

Courtesy of Eurostat

The spread is fairly wide — more than 38€.

The cheapest labor: Bulgaria with 5.4€ / $6 per hour

The most costly labor: Denmark with 43.5€ / $49 per hour

The Eurostat data showed that in 2018, hourly labor costs in the European Union averaged 27.4€ / $31 and 30.6€ / $34 in the countries that use euro as a currency.

Besides Denmark, you'd find high labor costs in countries such as Luxembourg, Belgium, Sweden and the Netherlands. The nations with the lowest rates include Romania, Lithuania, Hungary and Latvia.

In the global scale, the lowest average hourly labor costs can be found in Vietnam ($3), India ($2.5) and Indonesia (mere $0.8).

The share of non-wage costs of employment in the total labor cost reached an average of 24% in the EU and ranged from as little as 6% in Malta to as much as 33% in France.

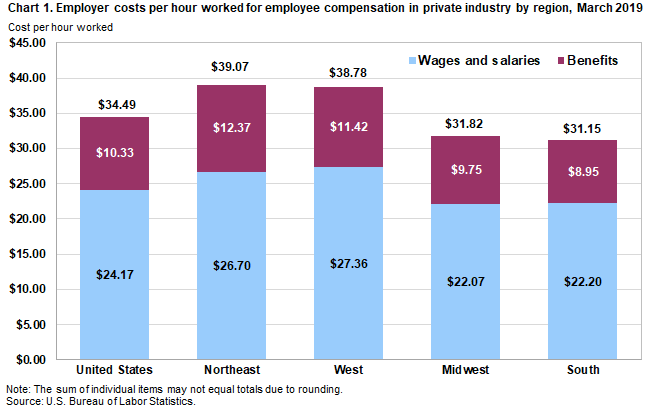

Courtesy of US Bureau of Labor Statistics

Data from the US Bureau of Labor Statistics shows that hourly labor cost in the US averaged $34 per hour. Benefits accounted for almost one-third of the costs in any of the regions.

What's more, the survey also highlighted regional differences that have their roots in history. The north-east, the most costly region, hits the roof with over $34 per hour, while the south barely exceeds $30 per hour.

From Walmart to Amazon

With labor costs rising around the world across almost all major industries, global employers are turning their attention to various methods to cut them down.

Walmart, for example, is introducing robot helpers to perform menial tasks such as monitoring inventory, cleaning floors, and unloading trucks.

These smart assistants help them reduce the time that workers spend on repeatable, predictable and manual tasks, letting them spend more time on customer service tasks that robots are not yet ready for.

Another example. Thanks to automation, Amazon now needs just a fraction of workers to sell and ship hundreds of millions worth of stuff than it did just a couple of years ago.

In addition, the tech giant decided to cut their labor costs by raising the minimum wage to $15. While this may at first seem illogical, it makes perfect sense in the long term.

Higher salaries will help Amazon retain their workers and reduce high turnover rates. This will, in turn, enable them to save money on recruiting and training new workers.

Robotic future

Industrial robots have been around for quite a while. They've surely done a lot of work that was — for us, human beings — too hard, too dangerous or just too mundane.

But Bill Gates, co-founder of Microsoft and currently the second richest person on the planet, argues that robots that take our jobs should also pay taxes.

He claims this is a way to slow down the spread of automation and to support other underfunded types of employment:

"Let us do a better job of reaching out to the elderly, having smaller class sizes, helping kids with special needs. You know, all of those are things where human empathy and understanding are still very, very unique. And we still deal with an immense shortage of people to help out there."

Gates' idea stems from the estimation that robots will create 15 million new jobs — killing 25 million jobs in the meantime — in the US in the next decade. According to a report by Forrester Research, this equals as much as 10% of the workforce.

And that's far from negligible.

The highway to prosperity

All different kinds of robots entered the workforce to help employers tackle multiple aspects of work — gain economic advantage, eliminate human error, increase work safety and maintain stable product quality.

But how will the rise of robots impact the development of labor costs in the future?

Labor costs around the world are expected to increase 6-7% annually. Robot costs — thanks to declining microprocessor prices — should remain level or decline.

In short, the presence of automation in the workforce helps us keep labor costs under control and will likely do so in the future.

And that's some very favorable conditions for an unprecedented growth of automation and artificial intelligence, to say the least.

Check out our diversified resume samples. They could lend you some inspiration for creating the resume that might just land you in your preferred pay bracket!